Pratica platform

Practically perfect in every situation

Bottero machining centres are extremely powerful and flexible machines that can produce many processing

operations with precision and reliability, such as profiling, drilling, edge finishing, cutting and much more. The ease and intuitiveness of the software are a great strong point for these machines that can be used in any advanced glass factory.

Main qualities

The high quality standard of the Pratica Plus range is particularly noticeable in the care for details: each component is carefully studied and designed to offer performance measuring up to the most demanding requirements, making the machine even safer and more performing.

After the success of the first version, the Bottero Pratica CNC workcentres evolve with their new PLUS version. Both 3 and 4 axes versions are equipped with the new high performance pressurised spindle.

The standard version of the machine is able to perform the following operations on glass sheets:

• Milling on the sheet with a rectilinear and/or curvilinear path.

• Edging and radial polishing on a straight and/or curved path on the edge of the sheet.

• Drilling and/or countersinking perpendicular to the surface of the sheet.

• Writing and drawing on the top side of the sheet.

By using optional aggregates the possibilities are expanded to:

• Cutting with a straight diamond disc.

• Cutting with a straight diamond disc angled at 45°.

• Writing and drawing on the side surface of the sheet.

• Straight and/or curved beveling on the top side of the sheet.

• Straight and/or curved engraving on the top side of the sheet.

• Straight and/or curved cup grinding on the side surface of the sheet.

• Drilling on the underside of the sheet.

Features

Bottero machining centres can operate both on glass and on stone, making their use even more flexible.Sheet clamping system

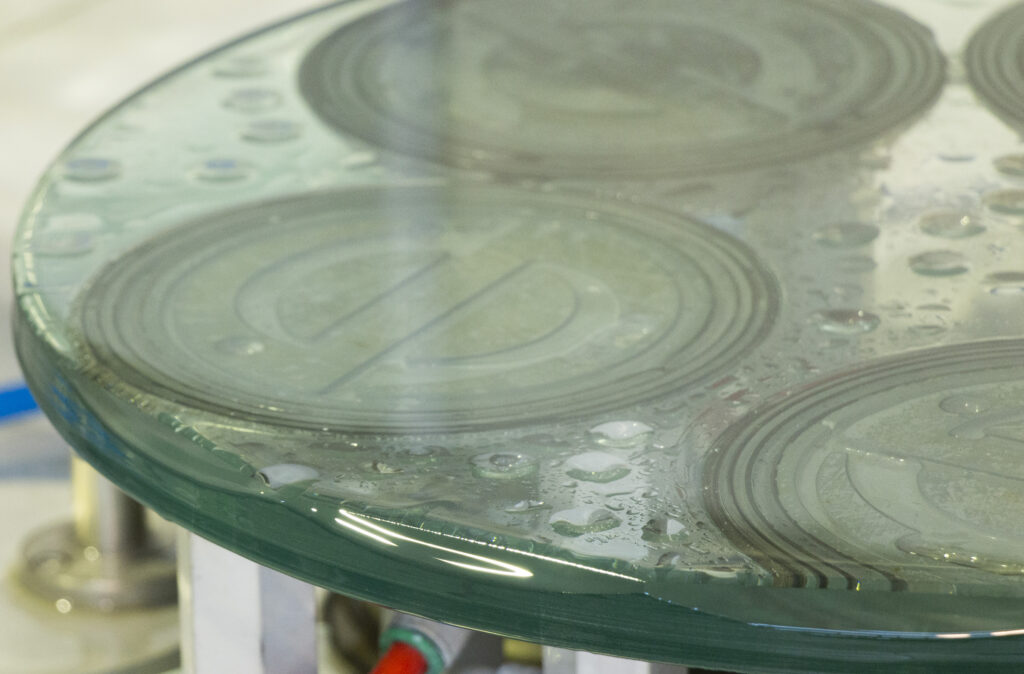

Sheet clamping system on the work table consisting in:

• Vacuum cups of different types so to be able to adapt to a wide range of different shapes to be processed; the vacuum cups are symmetric and therefore can be used in both directions (upside-down).

• Retracting telescopic stops to facilitate sheet positioning before machining.

• clamping circuits activated by manual control levers or pedal.

Electro-spindle

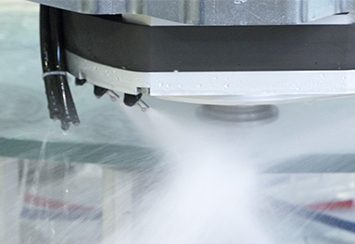

Including: • Self-ventilated air cooling.

• Pressurized circuit to prevent leakage of potentially dangerous pollutant particles..

• Water distributor for the flow of the “internal” tool cooling water for increasing the machining performance..

• “External” water distribution system (automatically filtered recycled water) supplied from special nozzles around the tool..

Tools magazines

Including: • Self-ventilated air cooling.

• Pressurized circuit to prevent leakage of potentially dangerous pollutant particles..

• Water distributor for the flow of the “internal” tool cooling water for increasing the machining performance..

• “External” water distribution system (automatically filtered recycled water) supplied from special nozzles around the tool..

Retractable tool magazine

Suction Cups and Work Table

The suction cups and stops are in turn secured to the work table (smooth and without any grooves of any type) again by means of a vacuum circuit, being connected to another dedicated circuit in which the vacuum is always present; in actual fact the suction cups are symmetrical and so can be used indifferently in one direction or the other. Because of the smooth work table with no grooves there are no limitations of any kind for positioning the suction cups and stops on it.

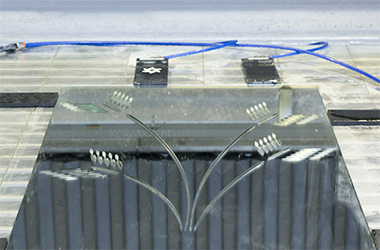

Matrix table

Either partially (50%) or totally (100%) covering the work area: innovative and fast positioning system for stops and suction cups avoiding the use of the traditional reference stop and without having to connect any pipe to supply air / vacuum to the various elements.

Shape scanner

Laser system for copying twodimensional shapes. By an almost automatic procedure, it is possible to scan the profile of a shape made of any material (including a drawn profile) in order to reproduce it accurately on a sheet of glass.

Technical specifications

Glass size

N° of modules

Machine dimension

Glass size

N° of modules

Machine dimension

Glass size

N° of modules

Machine dimension

Glass size

N° of modules

Machine dimension

Glass size

N° of modules

Machine dimension

Glass size

N° of modules

Machine dimension

Glass size

Maximum bridge speed:

Machine dimension

Glass size

Maximum bridge speed:

Machine dimension

Glass size

Maximum bridge speed:

Machine dimension