Vision

Main qualities

Bottero’s vertical edge grinding and bevelling machines allow the highest quality results to be achieved when processing edges, thereby guaranteeing a perfect finish and allowing use in the most elegant applications, in which quality is considered an essential element. The vertical edgers and bevelling machines are designed to ensure maximum production and maximum reliability. The availability of numerous machine set-up configurations allows you to choose the right product for both simple and extremely advanced processing operations.

Bottero straight line edgers and bevellers are built on a heavy duty electro-welded steel frame. Anti-corrosive materials are extensively used throughout the machine, such as stainless steel and water resistant technical polymers.

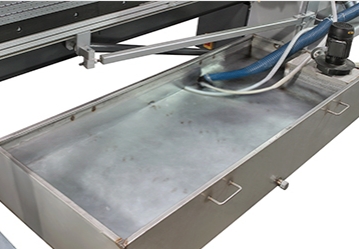

The water tanks are manufactured from stainless steel. This gives them greater longevity compared to other materials. Their design makes them easy to clean.

All parts coming into contact with water are manufactured from stainless steel. This guarantees that the mechanical components enjoy the longest possible lifespan. Straight line edgers and bevellers are designed to cope with 24 hour running. The machine needs only be stopped when the operator requires a break.

Features

With the aim of meeting all production needs, the BS cutting tables allow also fitting the cutting carriage with one of the various accessories available. Each constructive and functional features of the BCS range is designed to ensure extreme processing precision and maximum productivity, at the service of each specific production requirement.

Because they guarantee quality

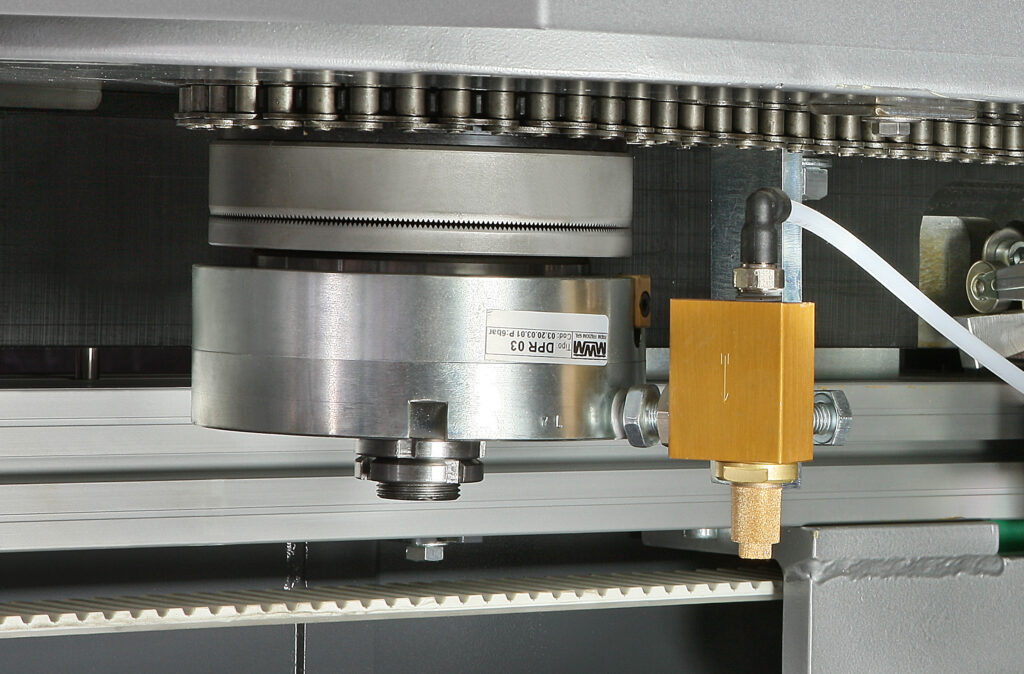

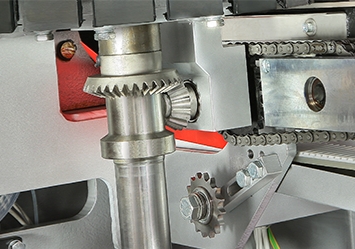

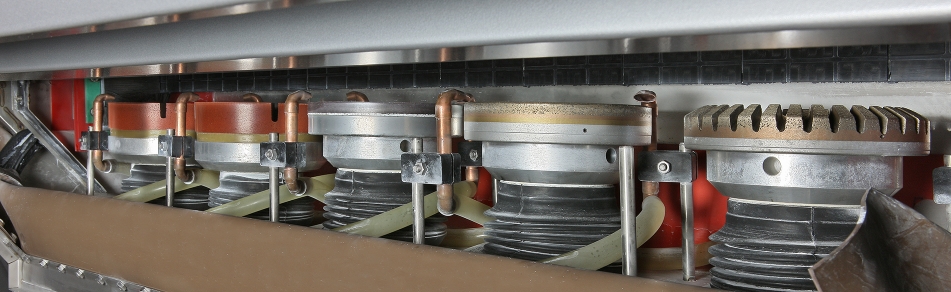

The heavy duty spindles eliminate any vibration that may affect the final product quality. The spindles are driven directly from the motor. This eliminates the need for drive belts and pulleys and drastically reduces the number of mechanical parts that may be subject to wear.

The in-feed conveyor belt system guarantees that the glass always enters the machine in a perfectly flat orientation. The in-feed drive can also be equipped with a pneumatic clutch to avoid any heavy belt wear.

Because they make sense