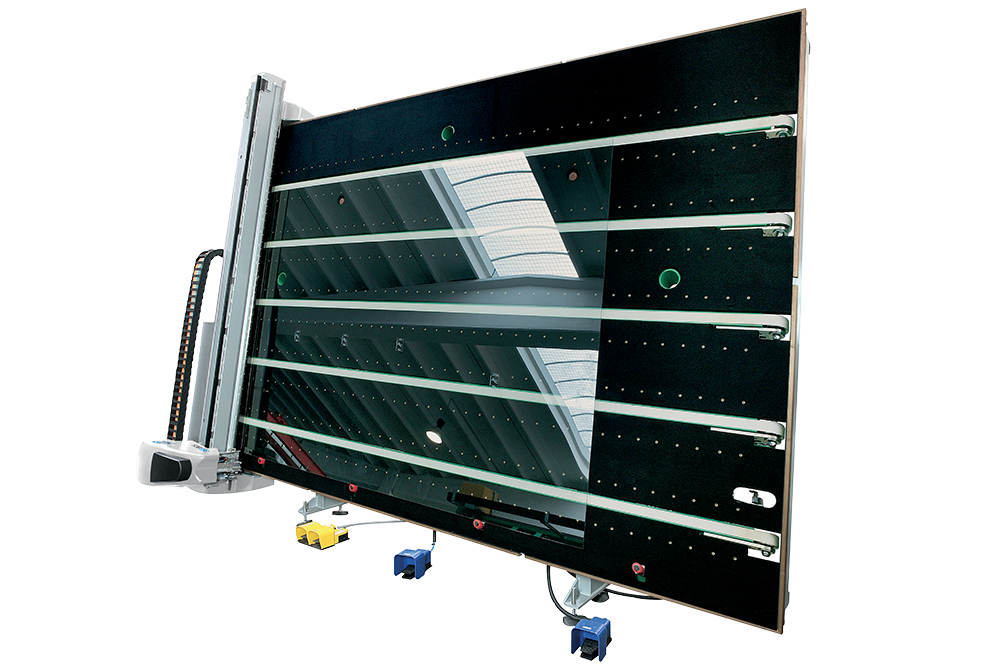

363 EVO

Loading, cutting, grinding, marking and breakout table fully integrated with manual or automatic loading and breakout modules and it can be coupled with cutting tables for laminated glass. The 363 EVO cutting table is available in the two fixed and tilting versions and is complete with air cushion with quick closing and belt conveyor, automatic selection of cutting pressures, Shape Scanner + Scan Cad, optimiser on the machine

and BCMS Windows.

Main qualities

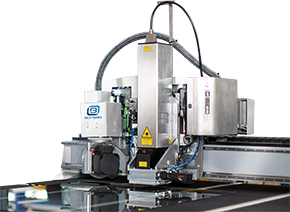

Surface removal system on Low-E glass with 200 mm peripheral wheel and maximum working speed of 200 m/min, is the ideal solution for large productions of low-emissivity glass. The approach stroke of the grinding wheel and its path are also optimised for shape cutting, allowing to speed up the machine cycle time, also thanks to the automatic measurement system of the grinding wheel consumption. You can install grinding wheels with different thicknesses for different production needs, and the wheel is also able to remove any protective films (TPF). The total coverage of the area being processed and the presence of the vacuum cleaner cancel the dispersion of dust in the environment, thus ensuring maximum safety for the operators.

The laser marking system is the solution for obtaining a permanent identification of the glass and can also be used to contribute in the organisation of post processing within the company. The CO2 laser system allows for high definition marking on the glass surface.

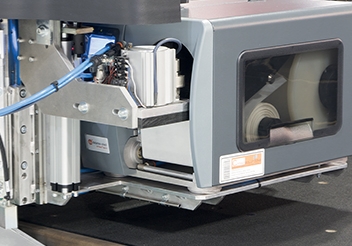

The automatic labelling system is the best solution to obtain the glass traceability and consequently more efficient organisation of the subsequent processes within the company. The labelling system fitted on the EVO cutting tables allows performing the labelling cycle and cutting cycle simultaneously, with total flexibility on the label position and on the printed text, ensuring a significant reduction of the machine cycle times.

Features

Cutting bridge

Carriage and cutting head

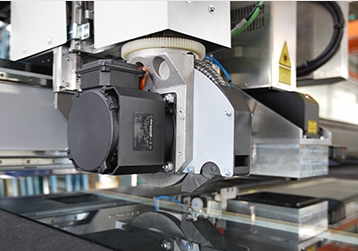

Cut: Motorised cutting head, formed by an aluminium alloy body and rod with cutting tool or plastic cut. Automatic glass thickness measurement by linear encoder and consequent automatic loading of the cutting parameters preset in the software. Cutting pressure adjusted by means of proportional solenoid valve and glass surface compensation system.

Safety: Glass presence detector and end element of the rod with controlled breakage, easily replaceable, to avoid mechanical stresses on the carriage and bridge in case of collision.

Carriage: Aluminium carriage with control and management electronics of the on-board head, complete with optical sensor able to perform the electronic squaring of the sheet and automatically acquire a shape thanks to the Shape Scanner system.

Bridge Handling