520 LAMe

520 LAMe is out best-seller meeting any customer’s need for the production of laminated glass. The automatic control of all parameters concerning the glass cut and positioning, and the possibility of removing a glass piece of 20 mm only, together with the removal of the low-e are the top class features of this machine.

Main qualities

Bottero’s portfolio of laminated glass cutting products meets any possible production needs in terms of formats and thickness, and ensures excellent cutting results even in case of 10+10 mm sheets.

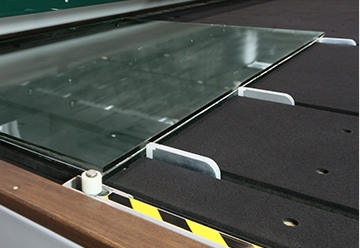

The positioning bridge, manual for 511LAM-S and automatic for 515LAMe and 520LAMe, helps the glass handling operations. The high density felt guarantees the best air floatation and avoids that glass chips get stuck inside with consequent potential scratching on the lower surface of glass sheets

The pneumatically operated arms on the working table allow smooth tilt of the glass sheet. Engineered to handle considerable weights and dimensions, these arms are the ideal instrument to efficiently load and unload large sheets.

The air cushion fan is directly fitted on the machine frame in order to obtain the max efficiency on the air cushion system. The shut-off system installed on the fan inlet allows the immediate interruption of the air cushion and, consequently, the risk of glass shifting.

Features

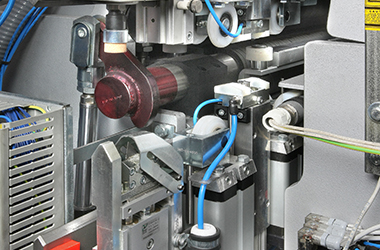

Blade cutting system

Blade cutting system (optional for 511LAM-S and standard for 515-520LAMe) is the best solution for customers processing glass with thick PVB layers. This system provides several benefits:

• Minimum heat of the glass.

• No waiting time between cuts.

• Avoiding delamination on PVB.

• High quality on the cut.

HP infrared heating element

HP infrared heating element

The HP infrared heating element concentrates the heating focus on the PVB layer rather than on the glass. Reduction of warming on glass surface avoids waiting time between cuts and allows significant savings on processing time. The two independent heating elements are automatically activated by the software according to the length and the position of the cut, thus allowing considerable energy and consequently economic savings.

Software

Guides: High precision and low noise bridge sliding guides, ground and installed on machined bed, ensuring a perfectly straight cut without the need for adjustment.

Racks : Ground racks, ensuring maximum positioning and cutting precision, and facing down to prevent the accumulation of dirt.

Materials : Components made of highly durable and minimal wear materials, ensuring optimal performance over time.

Carriage handling: High precision and low noise carriage linear sliding guides, ground and installed on machined surface.

Maintenance: Easily accessible components, ensuring immediate and fast maintenance.

Technical specifications

(*) Depending on type of glass and quality requirements.

(*) Depending on type of glass and quality requirements.