- Home

- Flex laminated lines

Flex laminated lines

Overview

Bring a contemporary design statement to your living space with our state of the art pivot doors.

Eurosystems delivers the security pivot doors with a unique vertical pivoting opening and offset axis. We provide the door system using innovative and sophisticated materials, which allows the designer to unleash his creativity in terms of architectural and functional design.

Up to 2 x 4 m

Maximum door leaf dimensions 2000 x 4000mm.

Each construction may be additionally extended by fixed elements or by glazing.

Two-sided

State-of-the-art technology and innovative fixing system ensure top quality of performance and use, as well as smooth door opening, disregarding the weight of the door leaf.

Technology

Maximum door leaf dimensions 2000 x 4000mm.

Each construction may be additionally extended by fixed elements or by glazing.

Up to 2 x 4 m

State-of-the-art technology and innovative fixing system ensure top quality of performance and use, as well as smooth door opening, disregarding the weight of the door leaf.

AGRM Glass Furnace For Sale

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

According to the furnace type, it can be divided into crucible furnaces, unit furnaces, regenerative chamber furnaces, full oxygen combustion furnaces, all electric furnaces, and hot top electric heating furnaces (composite furnaces).

Features

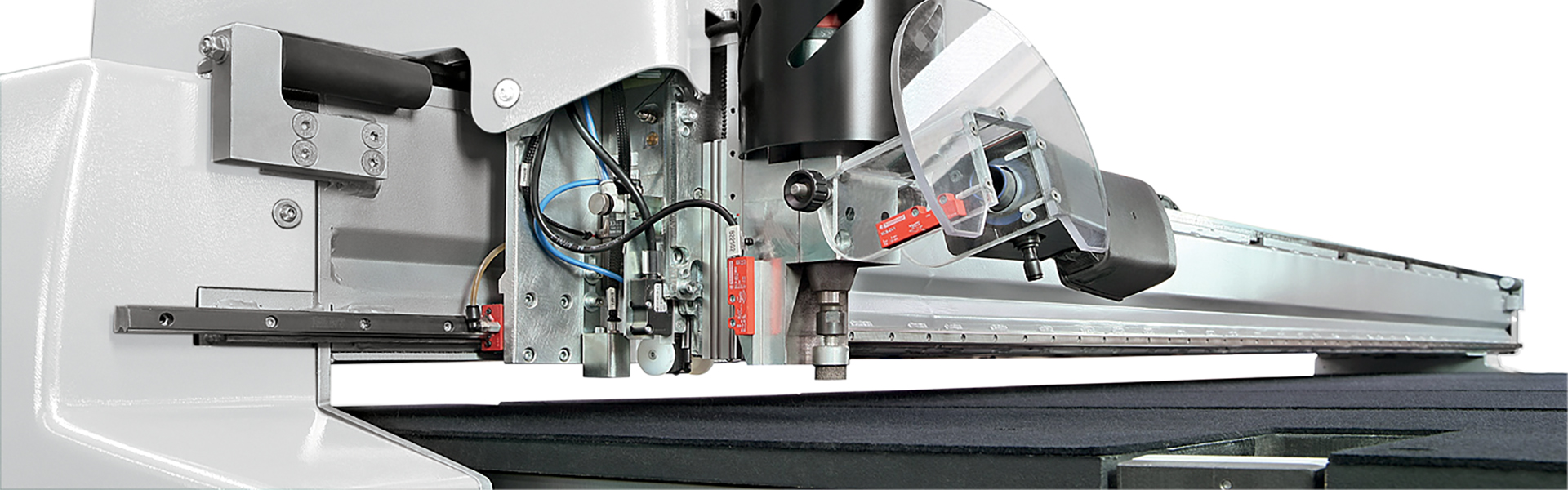

Cutting bridge

Structure

Drive

Transmission unit

Carriage handling

Carriage and cutting head

Cut

Safety

Trolley

Main qualities